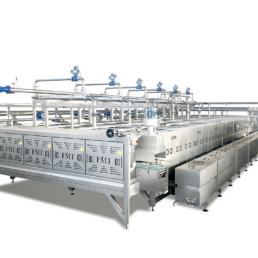

Monoblock for Hot Fill

SPEED from 3.000 to 60.000 BPH

(*) The dimensions of the Monoblocks and valves are calculated and sized according to the technical specifications of each project

The Hot Fill Monoblocks are developed to process glass or plastic bottles.

The Hot Fill technology is used for all those products defined as “non-carbonated” and that require hot filling to ensure their stability and product useful life.

The best technological solution is offered to meet the Customer’s needs, in relation to the design of the bottle and the product to be filled.

Specifications

The Monoblock can be developed with the typical Rinser + Filler + Capper configuration or the container “rinsing” phase can be excluded, if it is not required by the Customer.

The main function of this technology is to ensure:

- FILLING AT THE TEMPERATURE REQUESTED BY THE CUSTOMER

- CONSTANT LEVEL IN THE BOTTLE

Accessories

- Integration of the product pasteurisation module in the supply

- Possibility of working with low vacuum (glass only)

- Volumetric filling

- Possibility to process also CSD products

- Automatic dummy bottles (only on volumetric machine)

Contact Us

Request pricing or any additional information