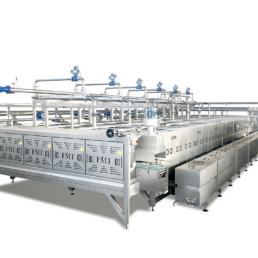

Monoblock with Flow Meter

SPEED from 100 to 700 CPM

Filling systems for glass, metal or plastic containers. Products handled: liquid, dense, semi-dense.

The range of products includes among others: tomato paste, jams, mayonnaise, ketchup, sauces, pâté, edible oils, creams, baby food, honey, yoghurt etc.

Operator interface with touch screen panel and simple, intuitive service menu;

Simple and fast format changeover;

Specifications

Features of filling and closing Monoblock Filltronic, with Flow Meter technology:

- High level of hygiene

- “No contact” filling valve

- Volumetric filling

- Modular base

- High flexibility

- Short format changeover times, settable on PLC

- Compact solution

- Automatic CIP

Accessories

The Monoblock Filltronic with Flow Meter technology can be configured with the following options :

- Mass or magnetic flow meter in relation to the conductivity of the product.

- Possibility of having, in the same base, several filling turrets in series.

- Covering of the monobloc with HEPA filters and overpressure of the internal environment

- Different types of cleaning treatment on containers before filling

- Container handling with neck gripping

- Doors openable vertically

Contact Us

Request pricing or any additional information