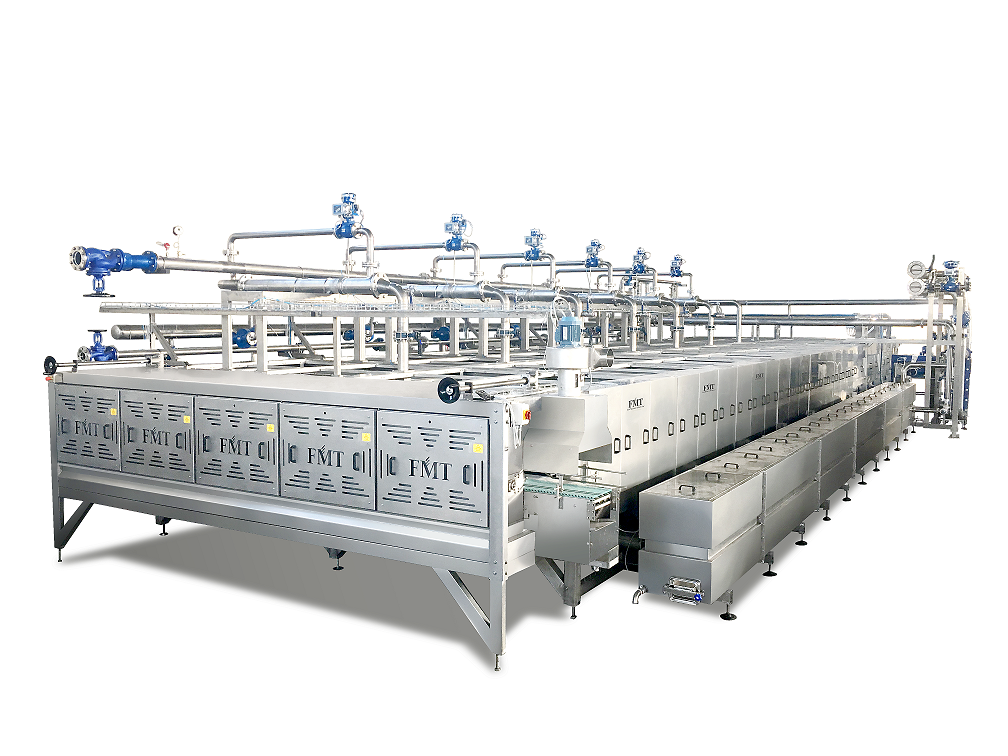

Cooler

The Cooling Tunnel is important to bring hot filled containers to a temperature of <40°C. This is an important phase of the production cycle which ensures product qualities inside a container, as it interrupts the product cooking process.

Our Cooling Tunnel is the result of the FMT know-how and stands as a top-of-the-range in a market that is increasingly demanding in terms of quality and efficiency.

It works with a heat exchange system, obtained by distributing water by gravity. This system achieves the best results in the time/temperature ratio.

Suitable for any type of container, such as: metal cans, jars, glass and plastic bottles, tubes, pouches, etc.

Specifications

- The FMT Cooler is made of AISI 304 stainless steel (except for some parts that are suitably designed with different materials).

- The machine is built in modules both for flexibility and transport reasons.

- The belt conveyor sliding surface is made with AISI 304 stainless steel profiles, suitably positioned, in order to avoid its wear.

- The belt conveyor is made of resistant modular plastic material.

- To facilitate positioning, the Cooler comes with adjustable feet.

- The top covers are made of stainless steel and are watertight.

- The water distribution showers located in the upper part of the entire machine, are fitted with quick release for maintenance.

- The tanks are positioned in the lower part and can be accessed from the side.

Accessories

- First module water heating by condensate recovery tubular heat exchanger;

- Water recovery system with plate exchangers;

- Side panels are also available as an option, for better accessibility.

- Machine infeed-outfeed Active Passage System that enables the elimination of dead plates in the belt passages;

Contact Us

Request pricing or any additional information