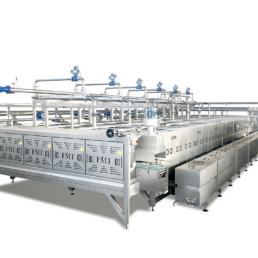

Capping machine US 800

SPEED from 500 to 800 CPM

(*) The speed depends on the size and type of cap

Closing systems for metal caps on glass containers. Processable caps: RTO-RTB-MTO-MTB-DTO-RTB, PT (PRY TWIST), SS (SIDE SEAL), DSR (SNAP RESEAL);

Constant closure when varying operating conditions;

Machine designed with “Operator Friendly” concept;

All surfaces inside the machine are designed and manufactured to facilitate draining and cleanability;

Simple and quick format change;

Specifications

The Capping machine uses the latest technologies to better meet the increasingly strict demands in terms of hygiene, cleanliness and reliability. Ideal in the food and beverage sectors.

This type of Capping machine, which works in-line on jars and/or glass bottles, allows to change quickly the format and high vacuum levels.

The US800 Capping machine, entirely manufactured in stainless steel, is designed by FMT to permit the closing of jars and glass bottles, having different types of caps, both with vacuum (steam technology) and dry;

A high capacity AV800 magnetic feeder can be supplied with the machine.

Accessories

- Headspace steam injection system: it is used to create the vacuum in the container and pre-heat the cap mastic;

- Steam superheating system; it is used for products sensitive to condensation water;

- Steam intake system; it is used to channel the steam through a pipe/hood (excluded from the supply), outside the working environment;

- Headspace nitrogen injection system: it is used for delicate products without vacuum;

- Hot air mastic warmer: it is used for products where steam can absolutely not be used;

- SEW Motorisations;

- Electrical height adjustment;

- Automatic lubrication system;

- Operator panel with PLC S7 + Siemens Touch screen;

Contact Us

Request pricing or any additional informatio