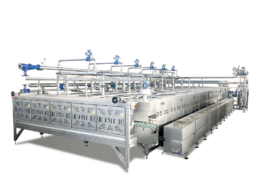

HORIZONTAL TUNNEL FOR PRODUCT THERMAL TREATMENT

It is a modular range of Tunnels for pasteurising, warming and cooling food products inside different types of container: cans, glass bottles and jars, plastic bottles.

The modular belt conveyor system ensures a

significant product stability, making operation extremely simple and reducing significantly maintenance.

The product can be handled on one or two stacked levels.

The simple operation and maintenance as well as the quality of the treatment performed, make the FMT Tunnels ideal machines for the pasteurising, warming and cooling cycles of all types of contain

An extremely flexible and innovative work platform, designed to meet the pasteurisation needs of the most demanding Customers.

Advanced technological solutions that enable FMT to manufacture machines at the highest levels available on the market today.

- Fast and accurate thermal treatment

- Maximum care for the most delicate products

- Modular configuration

- Energy saving systems

- Pasteurisation Tunnel

- Calorie recovery Pasteurisation Tunnel

- Heating Tunnel

- Cooling Tunnel

The various technologies of horizontal tunnels can be found in four machine versions: